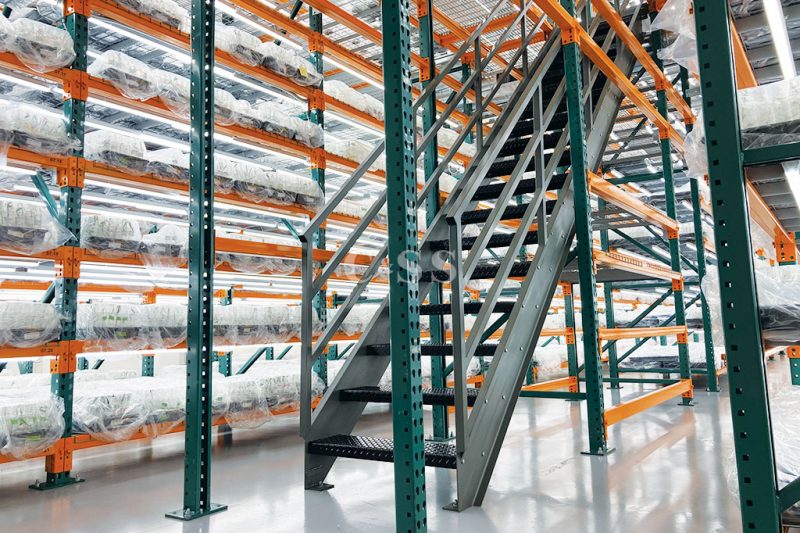

C&SS was able to complete the whole scope of work in just under 4 months, from initial design down to the last wire mesh deck being installed. AMFI was brought in to manufacture key components of the two-story pallet rack supported catwalk, the key deliverable in this project. It was designed with 18” shelving, accommodating focused lighting with plenty of room for seedling growth, all while maximizing the number of seedlings the system could hold. It was necessary to design the system with many different elevations to take advantage of as much density as possible, and so custom Hannibal uprights were designed and built to facilitate the structure. This ensured the material and specifications were perfectly suited to the project at hand. Conveyor and Storage Solutions was able to source used bar grating for the flooring of the catwalk system, saving the customer money without having to sacrifice any aspect of craftsmanship, quality, or time.

Case Study | Submitted by: Kurt Winbigler

Designed by: Martin Olsen

Installers: Jarrod Faul, Jeremy Keith, Jose Belman, Maui Ledesma, Senobio Saldivar

Rack Supported Catwalk for Seedling Nursery

Leading Agricultural Biotechnology Company | Orange, CA

CUSTOMER DESCRIPTION

Leading Agricultural Biotechnology Services Firm

The client is an agricultural biotechnology and services company specializing in date palm, arid, and semi-arid crop tissue culture. The company’s Plant Tissue Culture Laboratory is headquartered in Orange, California, where they operate a state-of-the-art 20,000 sq.ft. plant tissue culture laboratory dedicated to date palm and clonal rootstock development. Access to the highest quality mother trees, patent pending proprietary methods, proprietary varietals and superior products are a few of the Company's outstanding attributes. The company’s farms and greenhouses are located in California’s Coachella Valley, where their managing partners successfully farm thousands of acres, growing a variety of crops.

PROJECT SCOPE OF WORK

Design, Build of Catwalk System for Mass Clonal Seedling Propagation Nursery

The client has long been an industry leader in rapid clonal propagation. With disease on the rise and a steadily increasing market demand, the company felt the need to expand their production capacity. Meeting this goal required a new, larger facility in which to cultivate a wide variety of date palm seedlings. Their goal in starting this project was to create a facility capable of accommodating 400,000 date palm seedlings, situated in a new warehouse space adjacent to their current facility. Given just 3,200 sq ft. to work with, Conveyor & Storage Solutions took this as a challenge and got to work.

Decades of experience with density focused solutions resulted in a layout that blew the project’s stated goal out of the water. C&SS’s experts designed a pallet rack supported catwalk system capable of supporting over 580,000 seedlings. With a more than 45% increase in space optimization, the client was able to set themselves up for growth and success for years to come.

CUSTOM SOLUTION

Created Perfect Balance of Density and Growth Space for Maximum Yield

Extra care needed to be taken when physically building the structure, as the seedling nursery directly feeds a sterile laboratory. Special care had to be taken by C&SS’s expert installation team, including job-specific sanitization and cleaning procedures of all necessary equipment and materials. This level of attention to detail ensured that no compromises were made in the quality of work nor the safe and successful operation of the company’s future endeavors.

During the initial discovery and design phase, the building that would eventually be utilized as the nursery was occupied by office space. Measurements and design work occurred around this obstacle, keeping the project moving forward in a timely manner. Months later the office space was demolished, and it was found that some aspect of the design simply would not work given the new constraints. With component manufacturing already well underway, a creative solution was required. C&SS’s nimble design ethos again came into play, creating a new design that incorporated both the BOM and the new layout limitations that still exceeded initial project goals.

OUTCOMES

Increased Production Capacity While Saving Money

C&SS delivered a custom-tailored solution for the client, meeting or exceeding their goals for production capacity expansion with the following:

• Created a pallet rack supported catwalk system to function as a seedling nursery

• Exceeded customer’s initial space utilization goals by 45%

• Increased production capacity, improving profitability and decreasing lead times

• Utilized used materials to save money without sacrificing quality

• Project came in on time and on budget despite last minute design changes

THE C&SS DIFFERENCE

Protected Over 580,000 Seedlings

Throughout the initial discovery on through to the end of the build, C&SS distilled essential needs into quality solutions with:

• Innovative, industry leading design

• Custom solutions to complex problems

• A dedicated in-house installation team harboring extreme attention to detail

• The ability to quickly pivot and adapt as new challenges arose

• A commitment to great quality and excellent service at competitive rates