Portfolio | Submitted by: Larry Gonzalez

Designed by: Larry Gonzalez

Installers: Jeremy Keith

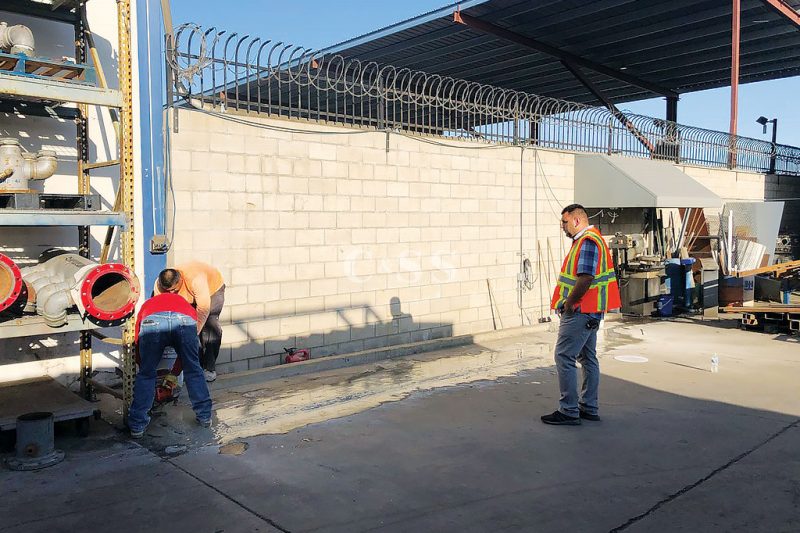

Cantilever Rack for Welding Storage

Total Environmental Management | Anaheim, CA

HANNIBAL STRUCTURAL CANTILEVER RACKING SYSTEM

Project Overview:

Total Environmental Management required a more efficient way to store raw material for their in-house fabrication team. After some discussion about specific goals for the project, Conveyor & Storage Solutions, Inc. designed and installed a structural cantilever racking system to best meet the needs of TEM.

CUSTOMER DESCRIPTION

Los Angeles Industrial HVAC Rental Company

Total Environmental Management Inc. was co-founded in June 1985 as an emergency/temporary air conditioning company serving the Southern California area. For over 30 years, TEM has provided important value by supporting large construction or retrofit projects with a rental supply of cooling and heating equipment, parts, and solutions. Today, TEM houses the largest inventory of any HVAC rental company on the West Coast. When TEM moved to Anaheim they greatly expanded their in-house equipment to support a wide range of applications. TEM has completed work throughout Washington, Oregon, California, Nevada, Utah, and Mexico.

PROJECT SCOPE OF WORK

Design and Installation of Structural Cantilever Rack Storage

Not long after relocating to a much larger facility in Anaheim, Total Environmental Management decided to invest in a storage system that more efficiently stored raw materials for their metal fabrication and welding shop. Their shop supports offsite job operations for their rapid response teams and found that their then current storage system was inadequate at best. By vertically storing, separating, and getting materials off the ground, C&SS was able to increase safety, functionality and efficiency. The Hannibal structural steel design is 100% Made in USA and ideally suited for heavy duty storage and outdoor use. Structural steel doesn’t have voids or pockets that retain water and can rust over time in an outdoor application the way a roll formed steel rack would. The arms have slight 4-degree pitch that helps keep tubular material from rolling of the rack, as well as an option for pipe stops that can be added at the end of the arms to keep pipe from falling off. It’s a true investment that pays for itself every day.

OUTCOMES

Improved Efficiency, Safety and Accessibility of Material Storage

Conveyor & Storage Solutions provided the following products and services:

• Designed and installed a structural cantilever racking system to better store raw materials

• Collaborated with Supreme Asphalt Services to provide new concrete footing and rebar support

• Delivered the project On-time and On-budget

• Produced a turn-key system to help TEM maximize their efficiency

• Project utilized locally built Hannibal structural steel racking