Description

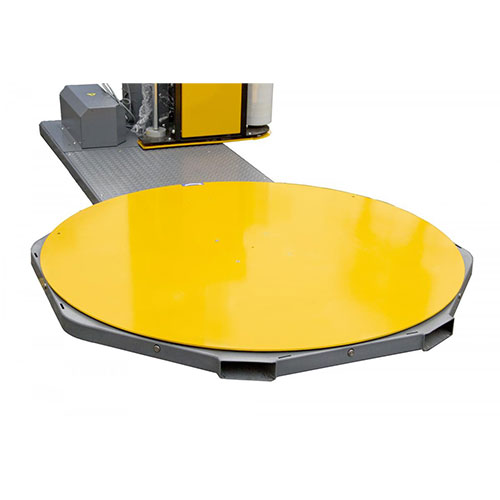

1100 Semi-Auto Stretch Turntable Wrap Machine

The Handle It® 1100 Semi-Auto Stretch Turntable Wrap Machine is a cutting-edge industrial packaging equipment designed to streamline and optimize the process of wrapping pallets and securing loads for shipping and storage. This advanced stretch wrap machine offers a combination of semi-automatic functionality and user-friendly controls, making it an ideal choice for businesses looking to enhance efficiency and productivity in their packaging operations.

The key feature of the Handle It® 1100 is its turntable design. The machine is equipped with a rotating platform or turntable on which the pallet is placed. This turntable is driven by a powerful motor, allowing it to spin at a controlled speed. The turntable rotation ensures that the stretch film is evenly applied to the pallet, resulting in a tight and secure wrap.

One of the primary advantages of the Handle It® 1100 is its semi-automatic operation. It simplifies the wrapping process by automating certain tasks while still requiring some manual intervention. The machine typically includes intuitive controls that enable the operator to adjust settings such as film tension, wrap cycles, and rotation speed. These adjustable parameters ensure that the stretch film is applied precisely according to the requirements of the load being wrapped.

The semi-automatic functionality of the Handle It® 1100 provides a balance between efficiency and flexibility. It eliminates the need for manual stretching and wrapping, saving time and reducing the physical strain on workers. The machine can be easily operated by a single person, allowing them to focus on other tasks while the wrapping process takes place.

Another notable feature of the Handle It® 1100 is its compatibility with a variety of stretch films. The machine is designed to work with both pre-stretched and conventional stretch films, giving businesses the freedom to choose the most suitable option for their specific packaging needs. Additionally, it can accommodate different film widths and thicknesses, ensuring versatility and adaptability to various load sizes and shapes.

The Handle It® 1100 is built with durability and reliability in mind. It is constructed from high-quality materials and incorporates robust components that can withstand the demands of heavy industrial usage. This ensures longevity and minimizes the need for frequent maintenance or repairs, contributing to the overall cost-effectiveness of the machine.

In summary, the Handle It® 1100 Semi-Auto Stretch Turntable Wrap Machine is a state-of-the-art packaging solution designed to enhance the efficiency and effectiveness of pallet wrapping processes. Its semi-automatic operation, user-friendly controls, and compatibility with various stretch films make it an excellent choice for businesses seeking to optimize their packaging operations. With its durable construction and reliable performance, the Handle It 1100 is a valuable asset for any company looking to improve their shipping and storage procedures.